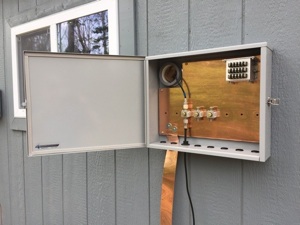

W1PEF photo

AA4XX photo

WV4R photo

What are the differences between the Defender Series™ entry panel boxes and the Interceptor Series™ junction boxes?

Entry panel boxes are designed for the following:

Designed to be mounted on wall of house. Provides convenient outdoor entry point for cables and arrestors.

Large hole in back of box allows cable passage through wall into house. Conduit can be used through wall. Cable flow is from bottom up.

Cables enter box via grommets or larger openings for conduit (or both).

Arrestors are lined up horizontally across box.

Boxes are horizontally oriented.

Can be made in galvanized steel, aluminum, or stainless in multiple gauges. Powdercoated in one of 20 colors.

Available sizes: (Height x Width x Depth)

Small 10x10x4”

Medium 14x14x4”

Large 14x17x4”

Extra large 16x20x4”

Junction boxes are designed for the following:

Designed to be mounted on tower, post, or otherwise serves as convenient wiring point between shack and tower. Can also be installed on our concrete mounting fixture.

Cables enter bottom of box via grommets or conduit (or both).

Boxes include copper bridge for rotor/control cables, putting them above coax arrestors to save space.

Arrestors are lined up vertically down box, and cables enter from bottom left, pass through arrestors, and exit bottom right (inverted U configuration for cable flow.)

Boxes are vertically oriented.

Are built in 16 gauge galvanized steel only, and powdercoated in one of 20 colors.

Available sizes: (Height x Width x Depth)

Medium 15x15x6”

Large 18x15x6”

Extra large 21x15x6”

Recently NG7M installed both a Junction Box and an Entry Panel at his QTH, and his great video shows both units plus give some detail on how to install them. His photo album shows more views as well.

Despite the different designs, either box can be custom configured with most features to suit your circumstances and needs. Call or email me for more information, Chris at KF7P dot com.

FAQ on Entry Panel Boxes:

How many grommet holes do the boxes come with?

How do the screws used to attach items to the copper sheet not end up going through the back of the box?

Can I fit a PL-259 (UHF connector) or N connector through the grommets?

What size conduit pipe should I run through the wall? I have ____ cables.

For _____ size conduit pipe, what size hole should I cut into my wall?

How do I seal up the cables as they enter the bottom?

Can I run conduit into the box, or do I have to use grommets?

How many cables can fit in a _____ size box?

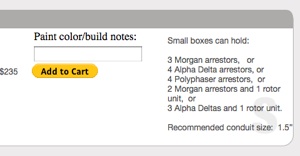

How many arrestors fit in _____ size box?

What if I want to run cables in/out the bottom of the box, not through the wall?

Can I put the hole for cables going through the wall in the bottom corner instead of the top?

Which arrestors should I select?

How long does it take to build and ship?

What comes with the box? What doesn’t come with the box?

Which material should I select? Steel, stainless, aluminum, fiberglass?

How do I tell you how I want this set up?

How do I finish off the inside of the wall where the cables come through?

Can you ship these internationally?

What is the thickness of the copper sheet in the box?

Answer: Every box is custom built to order, so as many as you need. However here are some guidelines:

Small box 4-6,

Medium 8,

Large 10,

Extra Large 12.

Answer: The copper sheet is on adjustable standoffs, holding it off the back of the box from 1/4” to 1/2”.

YES! Watch the “how to order an entry panel” video, it shows this.

Answer: Go with the recommended sizes listed to the right of the orange add-to-cart buttons. Remember that going through a wall is normally short (<12”) and straight. It is easy to get 7 cables with connectors through a 1.5” pipe; larger sizes even more.

Answer: 1.5” pipe is 1.90” OD, but the coupler which protrudes into wall is 2.25” OD.

2” pipe is 2.375” OD, but the coupler which protrudes into wall is 2.75” OD.

3” pipe is 3.5” OD, but the coupler which protrudes into wall is 4” OD.

Answer: Grommet to cable seals, found in the “accessories” section at the bottom of the entry panel page, are a simple and inexpensive way to do this. We highly recommend using these seals instead of cable glands, which are a PITA to work with because you have to install the coax connector on a 3” long piece of coax protruding through the bottom of the box. Not fun!

Answer: YES! Conduit up to 2” can fit in the bottom, side, or top of entry panels. 3” will only fit in the BACK of an entry panel (for going through the wall).

Answer: You’re asking the wrong question. Boxes are sized based on the number and type of arrestors being used. See the next question.

Answer: See the notes to the right

of the orange add-to-cart buttons.

Answer: Yes by all means, cables can go in/out the bottom instead of through the wall. Normally this means configuring the arrestors differently: Arrestors are lined up vertically down the center of the box, with cables coming in on the bottom left, doing a 90˚ bend, through the arrestors, another 90˚ bend, and exit the bottom right. Or vice versa. Consider getting a Junction Box instead of an entry panel as they are designed to be configured this way.

Yes, it’s not ideal but it can be done.

Arrestors are configured vertically.

Also watch “how to order an entry panel”

video.

Answer: Answer: All brands have pros and cons. Morgans are physically the largest, Alpha Deltas are the smallest. Polyphaser are the most expensive. Alpha Delta rely solely on a gas tube, but it is easy to replace. Alpha Delta will pass DC, Polyphaser block DC, Morgan can pass or block DC depending on the model. Morgan are the most sophisticated and have a true static drain feature. We use Morgan.

Answer: Depends on the current work load, but generally a few days to a few weeks.

Answer: The box comes as a bare unit, built as specified, with the copper sheet. Since every install is different, it does NOT come with any of the accessories. Grommets, plugs, seals, lugs, arrestors, mounting hardware, etc. are all optional accessories that you add-on at the time of the order. These can be added later if you forget (shipping can be adjusted if additional items are added and shipped together).

Answer: Galvanized, powdercoated steel is fine in most areas. If you are near the ocean or get copious amounts of rain, consider stainless steel. Aluminum is much lighter and holds up well in wet environments. 16 gauge is a little heavier/thicker metal, and more durable. 18 gauge is fine if mounted in low traffic areas. Fiberglass is also good in wet environments and fairly light.

Answer: Don’t worry, no work will be done until I contact you, usually by email and usually the same day I get the order. We will go over it together and set up a game plan.

Answer: Select any of these products to dress up the wall.

Keep in mind that they don’t interface with the conduit pipe;

the pipe simply “points” at the wall device.

Yes. Usually DHL or USPS Priority Mail International. Be prepared to open your wallet; it can easily cost $200 or more.

Answer: 18 gauge, or .050”. I also roll the edges over to create a more rigid sheet. Pictured below are four Morgan double units plus a single unit in the middle, in an XL entry panel box.

Morgan units attach with very short self drilling sheet metal screws. Alpha Deltas attach with a machine screw from the back side. Polyphasers can attach using either method but machine screws/nuts are recommended.

Coupler is larger diameter, requires larger hole in wall.

Theaded part fits into entry panel.